What are the types of hydraulic hose joints

Author:admin Date:2022-08-11

Since the hydraulic hose joint is a detachable connection element, it not only meets the requirements of normal connection stability, strong sealing, reasonable size, small pressure loss, good process performance, etc., but also needs to meet the requirements of convenient disassembly and assembly. Require. Therefore, don't underestimate the small pipe joints, because as long as it exists, it can support the existence of the entire hydraulic system. Today I will tell you what the types of hydraulic oil pipe joints are.

The connection methods of pipes and hydraulic hose joints in the hydraulic system are also different, and the connection thread is selected for the screw-in end of the pipe. The tapered thread is tightened by its own cone and sealed with PTFE and other substances, and is mainly used in medium and low pressure hydraulic systems. The sealing effect of fine thread is very good, and it is often used in high-pressure systems, but it requires the use of combined gaskets or O-rings to close the end face, and sometimes copper gaskets are used, which are more suitable for connecting the receiving wall. In thick pipes, the main components are the joint body, the receiving and the nut. In use, the joint body is embedded in the target, the hydraulic hose is used in conjunction with the gasket mentioned above to seal the end face, and the joint body and the receiver are sealed with rubber, and sometimes spherical sealing is used.

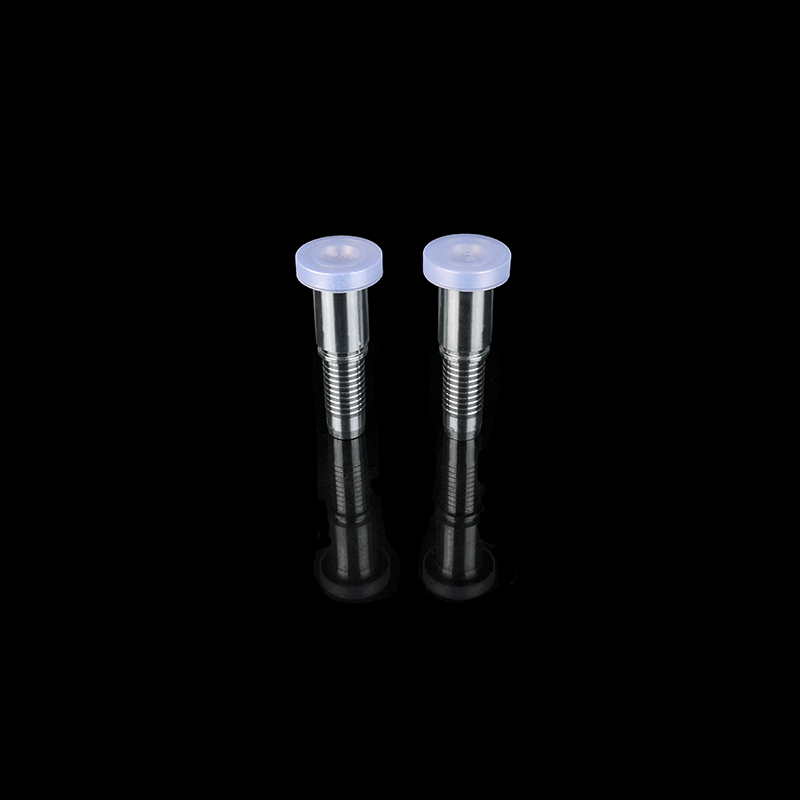

There are various types of hydraulic hose joints. Commonly used hydraulic hose joints can generally be divided into two types: hard pipe joints and hose joints. According to the connection method of the pipe joint and the pipeline, there are three types of hard pipe joints: flared type, ferrule type and welded type, and the hose joint is mainly a withholding type hose joint.

The outer rubber layer of the high-pressure hose is seriously deteriorated, and micro-cracks appear on the surface, which is the manifestation of the natural aging of the Eaton high-pressure hose. Due to aging and deterioration, the outer layer is continuously oxidized to cover the surface with a layer of ozone, and the hydraulic hose thickens over time. As long as the Eaton high-pressure hose is slightly bent during use, tiny cracks will occur. In this case, the Eaton high pressure hose should be replaced.

English

English 中文简体

中文简体 Español

Español