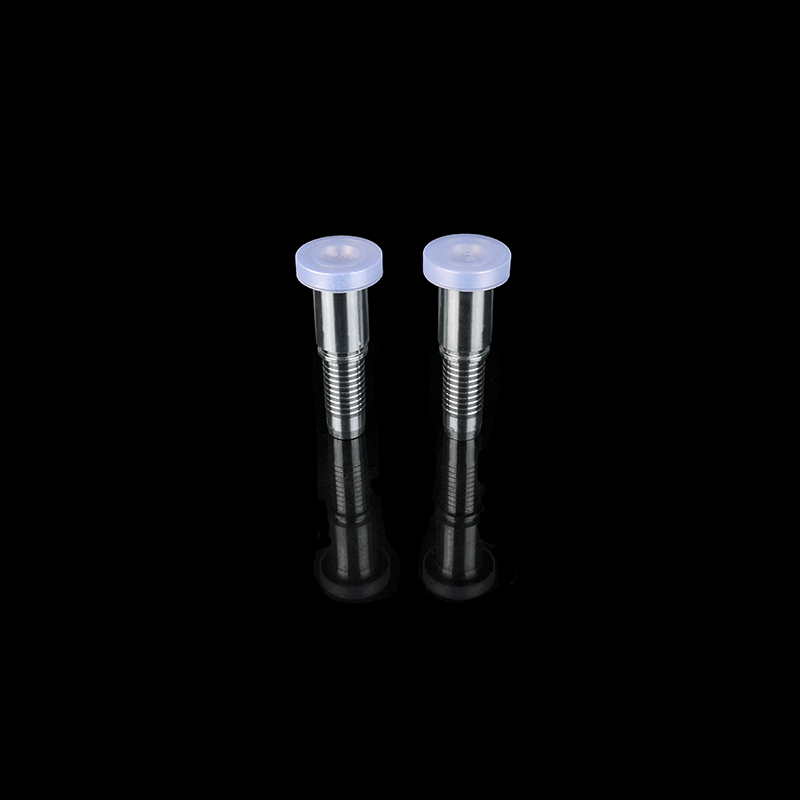

How to install the tube fittings?

Author:admin Date:2022-07-14

Installation steps of tube fittings:

(1) According to the requirements of Chapter 9, the pipes that need to be pickled should be pickled first.

(2) Cut the pipe with sawing machine or special pipe cutting machine and other equipment according to the required length. It is absolutely not allowed to use melting (such as flame cutting) or grinding wheel cutting; remove the inner and outer burrs, metal chips and dirt on the pipe end; remove the rust prevention of pipe joints agent and dirt; at the same time, ensure the roundness of the pipe.

(3) Put the nut and the ferrule into the pipe successively, the cutting edge of the front end of the ferrule (small diameter end) is at least 3mm away from the pipe mouth, and then insert the pipe into the taper hole in the body of the joint until it reaches it.

(4) Slowly tighten the nut, while turning the tube until it does not move, then tighten the nut 2/3 to 4/3 turns.

(5) Disassemble and check whether the ferrule has been cut into the pipe and whether the position is correct. The ferrule is not allowed to have axial movement, but can be rotated slightly.

(6) Re-tighten the nut after passing the inspection.

Pre:How to prevent leaks at hose joints

Next:What are the types and specifications of commonly used metal hose joints?

Next:What are the types and specifications of commonly used metal hose joints?

English

English 中文简体

中文简体 Español

Español