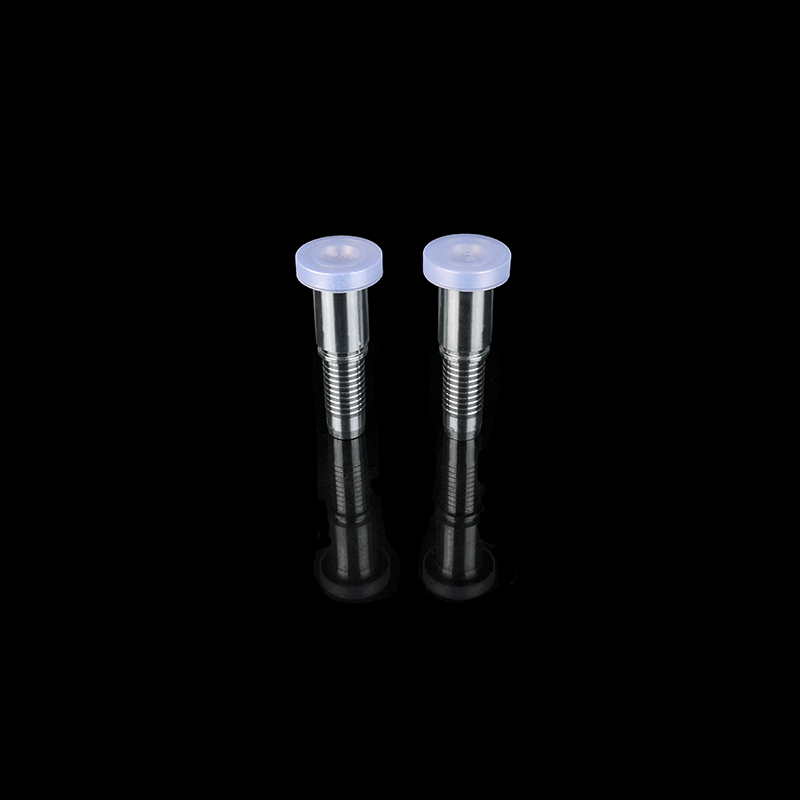

Do you know the steps in the assembly of the ferrule type fitting (1)?

Author:admin Date:2022-07-01

(1) Pre-installation

①The most important part of the pre-installation of the ferrule type pipe joint directly affects the reliability of the seal. Usually a dedicated preprocessor is required. Fittings with small diameters can be pre-assembled in a vise. The specific method is to use a joint as the mother body, and press the nut and the ferrule onto the pipe. There are mainly ferrule-type straight-through pipe joints, ferrule-type end-through joints, ferrule-type three-way pipe joints and other types. The author found that even if it is a batch of goods from the same manufacturer, the depths of the conical holes on the joint bodies are often different, resulting in leakage, and this problem is often ignored. The correct way is, what kind of joint body is used to connect one end of the pipe, and the corresponding connection end is pre-assembled with the same type of joint, which can avoid leakage problems to the greatest extent.

②The end face of the pipe should be flush. After the pipe is cut off, it should be polished on a grinding wheel and other tools, and the burrs should be removed, cleaned and blown with high-pressure air before use.

③ During pre-installation, the coaxiality of the pipe and the joint body should be kept as far as possible. If the deflection of the pipe is too large, the seal will fail.

④ The preloading force should not be too large so that the inner edge of the ferrule is just embedded in the outer wall of the pipe, and the ferrule should not be deformed significantly. When connecting the pipes, assemble them according to the specified tightening force. The tightening force of ф6-1 ferrule is 64-1 15n, 16фmmr 259n, and ф18mm is 450n. If the ferrule is severely deformed during pre-installation, the sealing effect will be lost.

Pre:What are the types and specifications of commonly used metal hose joints?

Next:What types of fittings do you know(2)?

Next:What types of fittings do you know(2)?

English

English 中文简体

中文简体 Español

Español