Types and characteristics of oil pipes and pipe joints in hydraulic systems

Author:admin Date:2021-09-09

In hydraulic systems, oil pipes and pipe joints seem to be unimportant, but they are actually very important. There may be many oil pipes and pipe joints in a hydraulic system, and their types and characteristics may be different. The following Dalan Hydraulics editor will take you to understand the types and characteristics of oil pipes and pipe joints in the hydraulic system.

1. Tubing

In the hydraulic transmission system, the commonly used oil pipes include steel pipes, copper pipes, nylon pipes, plastic pipes, rubber hoses, etc.

① Steel pipe: can withstand high pressure, the oil is not easy to oxidize, and the price is low, but it is difficult to assemble and bend. Commonly used No. 10 and No. 15 cold-drawn seamless steel pipes are mainly used in medium and high-pressure systems.

② Red copper pipe: It is convenient to bend during assembly, and the inner wall is smooth, and the friction resistance is small, but it is easy to oxidize the oil, the pressure resistance is low, and the vibration resistance is poor. Generally applicable to medium and low-pressure systems.

③ Nylon tube: It is convenient to bend, low in price, but has a short life span. It can partially replace the copper tubes in medium and low-pressure systems.

④ Rubber hose: It is made of oil-resistant rubber clamps with 1-3 layers of steel wire braided mesh or steel wire wound layers. It is characterized by easy assembly, which can reduce the impact of the hydraulic transmission system and absorb vibration, but it is difficult to manufacture, expensive and has a short lifespan. Generally used for connections between relatively moving parts.

⑤ Oil-resistant plastic pipe: low price, easy to assemble, but low-pressure resistance. Generally used for leaking oil pipes.

2. Pipe joints

Pipe joints are used for connection between oil pipes and oil pipes, and between oil pipes and hydraulic components.

Suitable for the connection of copper pipes or thin-walled steel pipes. It can also be used to connect nylon pipes and plastic pipes. It is commonly used in general machine tool hydraulic systems with low pressure.

Suitable for the connection of copper pipes or thin-walled steel pipes. It can also be used to connect nylon pipes and plastic pipes. It is commonly used in general machine tool hydraulic systems with low pressure.

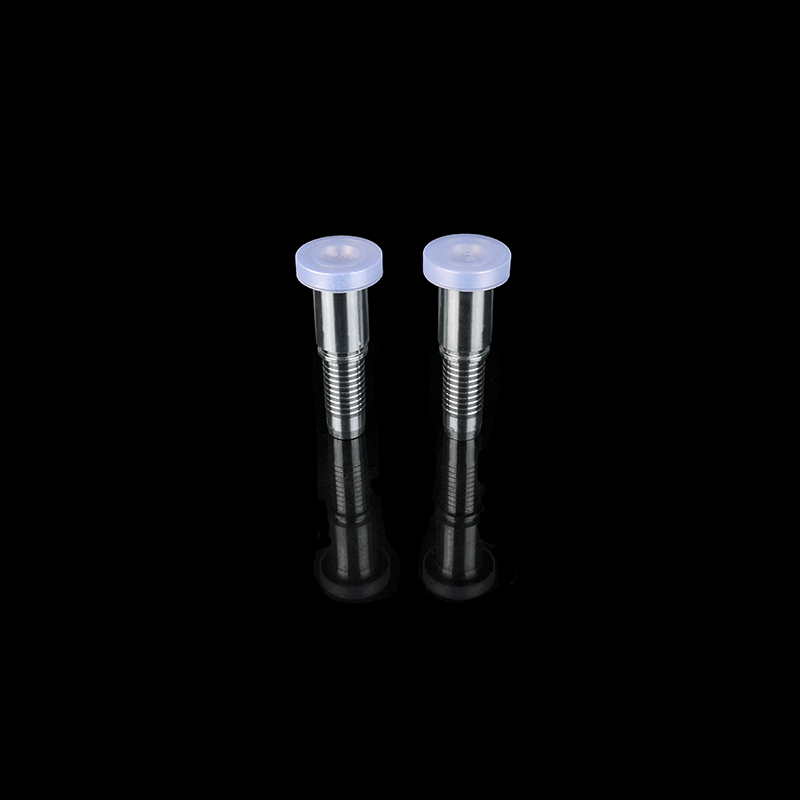

Used to connect steel pipes with thicker walls, and used in a hydraulic transmission system with higher pressure.

When the nut of the pipe joint is tightened, the tapered surfaces at both ends of the jacket are used to elastically deform the jacket to clamp the oil pipe. This type of pipe joint is easy to assemble and disassemble, and is suitable for steel pipe connections of high-pressure systems, but has high manufacturing process requirements and strict requirements on oil pipes.

Which is mostly used for the connection of rubber hoses in medium and low-pressure systems.

English

English 中文简体

中文简体 Español

Español