Which fitting types (1) do you know?

Author:admin Date:2022-06-13

| type | Features | Standard |

| Welded pipe joint | Weld the tube to the tube. The end face of the joint body and the nozzle is sealed with an O-ring seal. The structure is simple, the manufacture is easy, the sealing performance is good, and the dimensional accuracy of the pipe is not high. The welding quality is required to be high, and the assembly and disassembly are inconvenient. The working pressure can reach 31.5MPa, and the working temperature is -25~80℃. It is suitable for the pipeline system with oil as the medium. | JB966~1003-1977 |

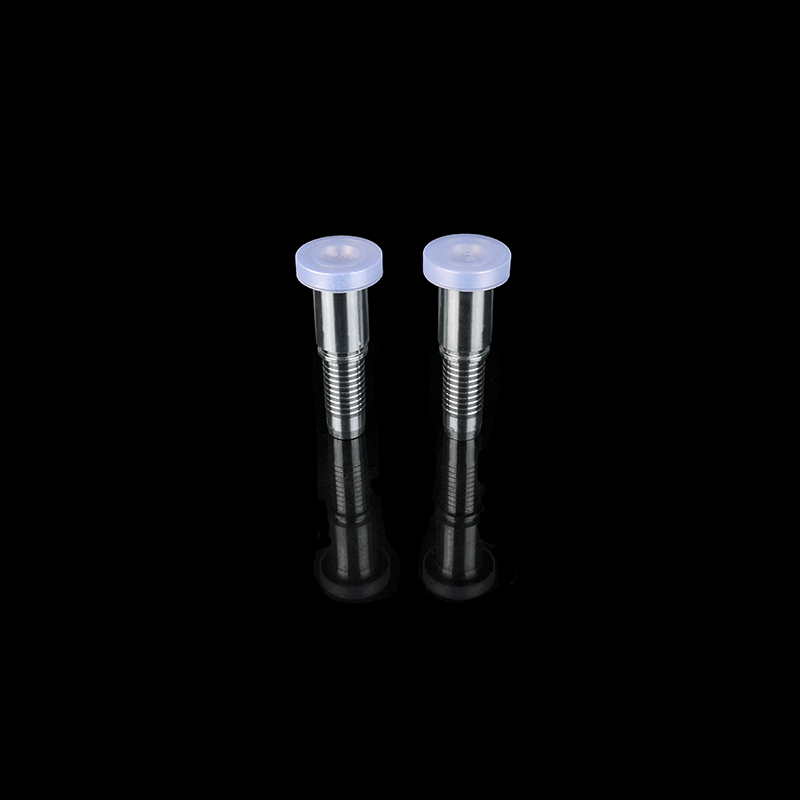

| Tube Fittings | Using the ferrule to deform the pipe and seal it, it has advanced structure, good performance, light weight, small volume and convenient use, and is widely used in hydraulic systems. The working pressure can reach 31.5MPa, and the dimensional accuracy of the pipe is required to be high, and cold-drawn steel pipe is required. The precision of the ferrule is also high. Pipeline system suitable for oil, gas and general corrosive medium | GB3733.1~3765-1983 |

| Flare Fittings | Sealed with tube end flares, no additional seals are required. Simple structure, suitable for connecting thin-walled pipe fittings It is suitable for the pipeline system with low pressure with oil and gas as the medium, and the pressure is allowed to be used. |

GB5625.1~5653-1985 |

| Insert Welded Fittings | Insert the pipe of the required length into the pipe joint until the end face of the pipe is in contact with the inner end of the pipe joint, and weld the pipe and the pipe joint into one body. | JB3878-1985 |

| Cone Seal Welded Fittings | One end of the nozzle is the outer cone surface and the O-ring is matched with the inner cone surface of the joint body, and is tightened with threads. The working pressure can reach 16~31.5MPa, and the working temperature is -25~80℃ Suitable for pipeline systems with oil as medium |

JB/T6381~6385-1992 |

English

English 中文简体

中文简体 Español

Español