Precautions for installation of hydraulic hose joints

Author:admin Date:2022-11-17

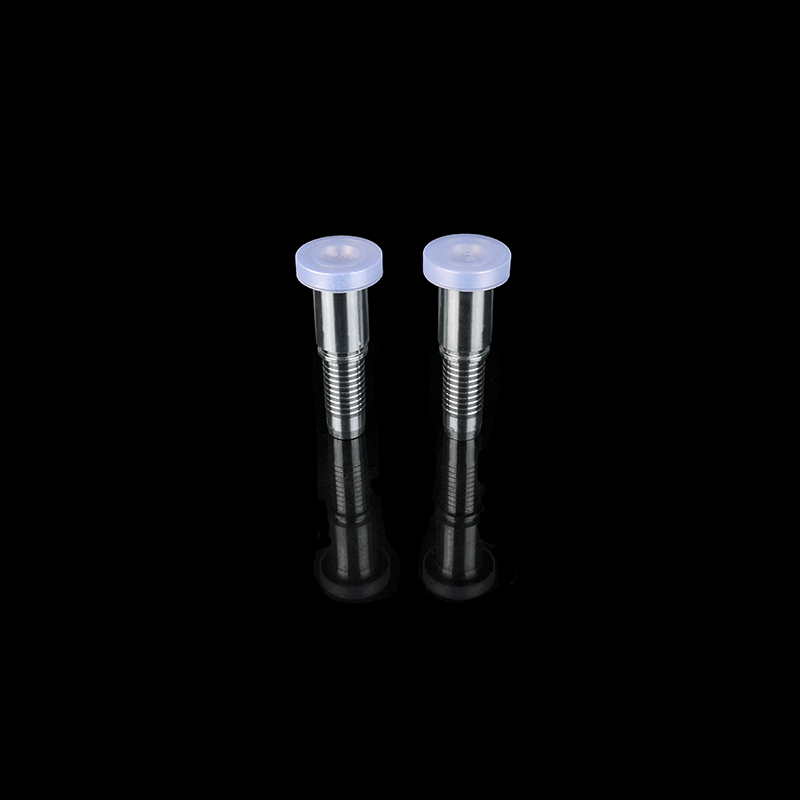

Pre-installation of hydraulic hose fittings is an important stage that immediately jeopardizes the stability of the seal. Usually, it must be a special type of preheater. Piping can be pre-assembled on a vise with small hydraulic hose fittings. This is done by using hydraulic hose fittings and clamping nut and ferrule fittings to the pipe. The main forms include ferrule-type straight pipe hydraulic hose connectors, ferrule-type end direct access connectors, ferrule-type three-way hydraulic hose connectors, etc.

Hydraulic hose fittings editors have found that, even with shipments from the same manufacturer, the tapered hole depths on these types of hydraulic hose fitting bodies often vary, and hydraulic hose fittings cause leaks, which are often overlooked. The correct way is to use what kind of hydraulic hose connector body to connect one end of the hydraulic hose connector, and the matching connection end of the hydraulic hose connector is pre-installed with the same type of hydraulic hose connector. Hydraulic hose fittings can prevent hydraulic hose fittings from leaking to a great extent.

The bores of hydraulic hose fittings should be flush. After the hydraulic hose joint pipe is sawed off, it should be polished on a special tool such as a grinding wheel, and the burrs should be removed. Before use, hydraulic hose connectors should be cleaned and purged with high-pressure gas. When pre-assembling hydraulic hose fittings, the parallelism between the hydraulic hose fitting tube and the hydraulic hose fitting body should be maintained as much as possible. If the hydraulic hose connector is angled too far, the seal will not be effective.

For the hydraulic hose joints of flared tubes, most of them have too much flare, the quality of hydraulic hose joints does not meet the requirements or has been disassembled many times, resulting in leakage of hydraulic hose joints, such as flaring deformation or cracks. At this point, the front can be cut off and unfolded again. If the top pressure of the male cone and the female cone is used for sealing, most of the leakage is based on the damage of the two spherical surfaces. In some places where the hydraulic hose joint is sealed by the inner hole or diameter, the abrasive grinding surface can be used.

The reasons for the leakage are as follows: the leakage is caused by the aging or deformation of the hydraulic hose joint; the hydraulic hose joint is not installed in time, the pressure of the hydraulic hose joint is uneven when connecting two planes, or the hydraulic hose joint is laser cut, resulting in leakage; The hydraulic hose joint is not pressed tightly, and the elastic deformation is too large, resulting in leakage; the groove of the hydraulic hose joint is too deep, resulting in leakage.

For this reason, hydraulic hose joints need to re-select hydraulic hose joints with the same diameter and thicker section. It is also possible to drill or cut the sealing scheme of the hydraulic hose joint with grooves to reduce the depth of the groove of the hydraulic hose joint so that the hydraulic hose joint has sufficient elastic deformation.

For acid and alkali resistant rubber sheets, felts, hydraulic hose joints, alloy steel cardboard, and leaks at hydraulic hose joints of pipes that form seals or sealants, regardless of the material of the hydraulic hose joints, hydraulic hose The joint should first check whether the seal is damaged, deformed, aged and the surface roughness is too large, and then take effective countermeasures for the hydraulic hose joint.

Pre:Selection and Application of Uniform Thread for Hydraulic Hose Joints

Next:What is the best material for hydraulic seals?

Next:What is the best material for hydraulic seals?

English

English 中文简体

中文简体 Español

Español