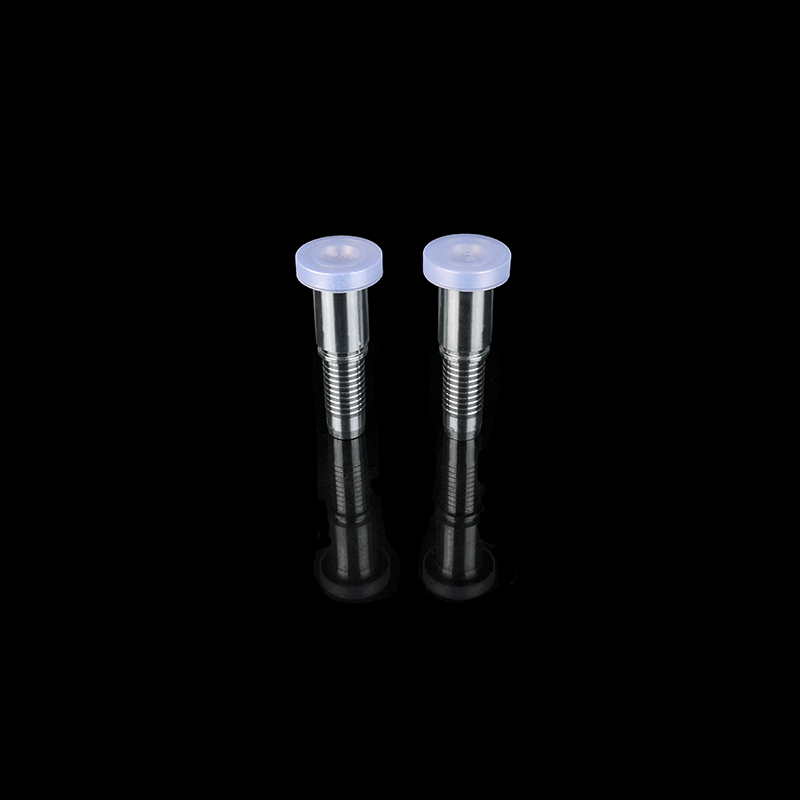

How to prevent leakage of hose joints

Author:admin Date:2022-10-24

You must know that both metal joints and hose joints are very prone to leakage problems. In most cases, the ferrules are loosened or deformed due to the large external force or impact force on the pipeline. Therefore, we need to check the card frequently. Whether the sleeve is out of round and whether the cutting edge is worn, if the pipe end and the ferrule nut are not pressed tightly, the external force of the pipe will be in a state of tension, which will cause excessive flaring. If the hose joint leaks due to damage to the two conical surfaces, it is necessary to grind the conical surfaces with abrasive sand.

For various types of hose joints, we have to adopt different installation methods. Among them, when the hose is moving or stationary, we cannot allow it to bend excessively, and should be bent at 1.5 times its diameter. It was pulled to extreme positions during installation, and we wanted to keep it loose, too tight would twist it. If you are installing a high-pressure hose, remember to keep it away from radiating components and install a heat shield if necessary.

Pre:Thread grade and size of the threads of hose fittings

Next:How to install hydraulic hose joints to ensure good air tightness

Next:How to install hydraulic hose joints to ensure good air tightness

English

English 中文简体

中文简体 Español

Español