How to keep the interface tight with high-quality hydraulic pipe fittings hydraulic hose?

Author:admin Date:2023-02-02

To ensure a tight interface with high quality hydraulic pipe fittings hydraulic hose, it's important to follow a few best practices:

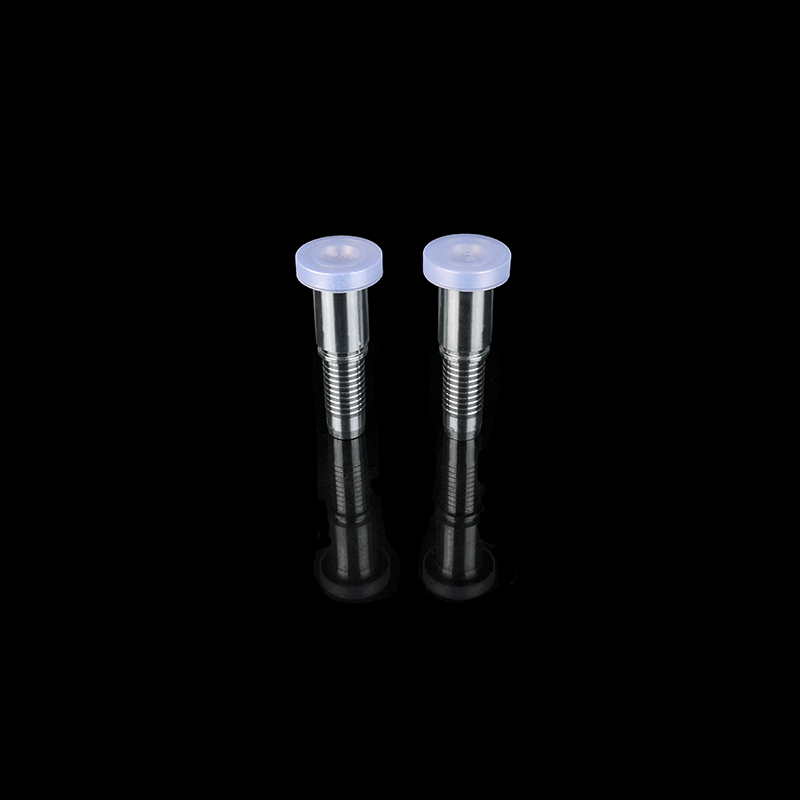

Choose the right fitting and hose for your system: Make sure the fittings and hose you choose are compatible with your system's fluid and pressure requirements.

Proper installation: It's crucial to follow the manufacturer's instructions for installation, ensuring that the fittings are tightened to the correct torque specifications.

Regular maintenance: Inspect your fittings and hose regularly for any signs of wear or damage and replace them promptly.

Avoid over-tightening: Over-tightening can cause damage to the fittings or hose, leading to leaks.

Use proper tools: Use the proper tools for cutting and crimping the hose and fittings to ensure a clean and accurate fit.

By following these best practices, you can help ensure a tight and secure hydraulic interface, which will help prevent leaks and other issues that can affect the performance and longevity of your system.

Pre:No previous article

Next:What are the requirements for construction machinery hydraulic hose Ferrule?

Next:What are the requirements for construction machinery hydraulic hose Ferrule?

English

English 中文简体

中文简体 Español

Español